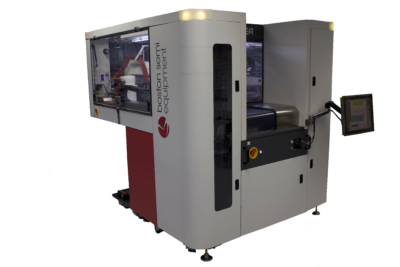

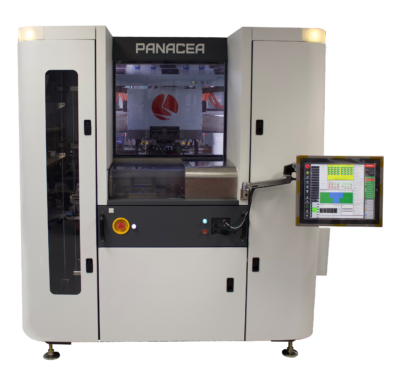

Panacea

The Next Generation of Pick & Place

“Panacea’s vision-enabled flow allows customers to standardize the test floor like never before with World-Class Thermal Accuracy, Process Flexibility and Hassle-Free Uptime.”

– Colin M. Scholefield, Senior Director Product Marketing

About Panacea

“Panacea’s vision-enabled flow allows customers to standardize the test floor like never before with World-Class Thermal Accuracy, Process Flexibility and Hassle-Free Uptime.”

– Colin M. Scholefield, Senior Director Product Marketing

Technology change is happening at a rapid pace adding new die package test handling challenges and complexity. BSE is responding to help our customers stay ahead of the game with its refined generation of Pick–and–Place automation – Totally Reimagined to adapt to the most challenging applications both today and well into the future. Panacea’s vision-enabled flow allows customers to standardize the test floor like never before with World-Class Thermal Test Accuracy, Process Flexibility and Hassle-Free Uptime.

Panacea’s future-proof design eliminates the need for complex device transfers within the test handler. Simplified, 3-stage device movement reduces touch points, minimizes semiconductor package-specific hardware during changeovers, and frees the handler to work for you no matter how differentiated your product portfolio.

Why Panacea?

- Wide-Open, Chamberless Design for Quick Access and Flexibility

- +/- 1°C Thermal Accuracy at Test Site for Demanding Applications (Tri-Temp Version)

- +/- 25µm Positioning Accuracy (High-Accuracy, Ambient Version)

- Up to 40% Savings in Kit Costs Per Year*

- Up to 15% Savings in LN2 Consumption Per Year*

* Application and local costs dependent

- Standard Integrated Vision System

- Patented Soak and Staging Process

- Chamberless Environment

- World-Class Thermal Accuracy

- Custom Product Paths for Unique Packages

Available in the Following Configurations: