Custom Automation Solutions

Uniquely Designed for You

“We thrive on tackling the complex and unforeseen problems of new and existing customers and bringing our innovations to market.”

– Colin M. Scholefield, Director of Product Marketing

About Custom Automation Solutions

BSE works with customers to solve unique applications challenges that require custom designed test handling solutions. Our team of experienced engineers bring decades of system design know-how. As a result, BSE is recognized as a high-quality producer of application-specific test handler equipment for some of the largest global semiconductor manufacturers. Working closely with your team, we can tackle any specific need big or small.

Examples of our custom automation solutions include:

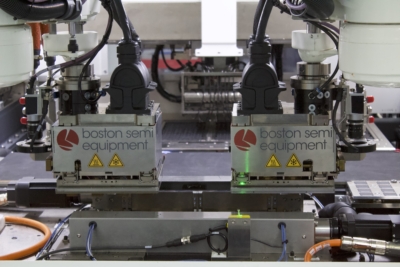

BSE-900

The BSE-900 is a compact test handler design ideal for engineering and low volume production test environments. The BSE-900 can interface to two testers with each connection able to load one (1) to four (4) test sites; or it can be used to load multiple System Level Test (SLT) positions.

The system integrates JEDEC tray automation, vision alignment, and 2D ID reading for semiconductor packages from 3mm x 3mm to 120mm x 120mm with thickness up 20mm.

For larger, high-pin-count packages, a combination of cameras and mechanical precising ensure +/-75µm placement accuracy. The integration of 2D ID reading makes the BSE-900 ready for smart manufacturing environments.

The BSE-900 can be run ambient, interfaced with thermal test forcing systems for testing at temperature, or integrated with anechoic chambers for 5G over-the-air testing.

- Small to Large Packages (Up To 120 x 120)

- 15 Minutes Package-to-Package Changeover

- Final or System-Level-Test

- Adaptable for 5G Over-The-Air Device Testing

- Interfaces with One or Two Testers

- x1 to x4 Parallelism

- 2D ID for Smart Manufacturing

- Vision Alignment

- Industry 4.0 Ready

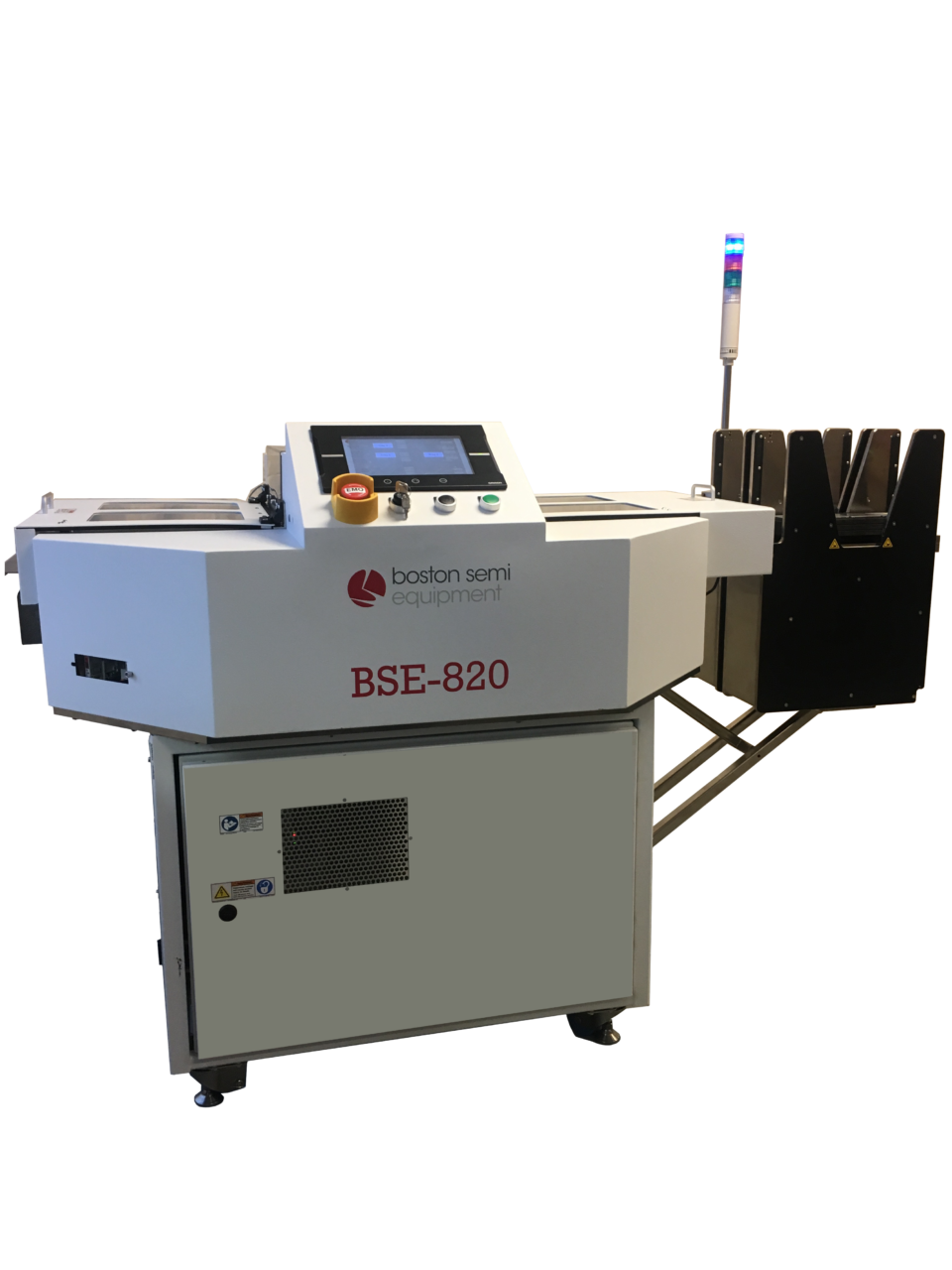

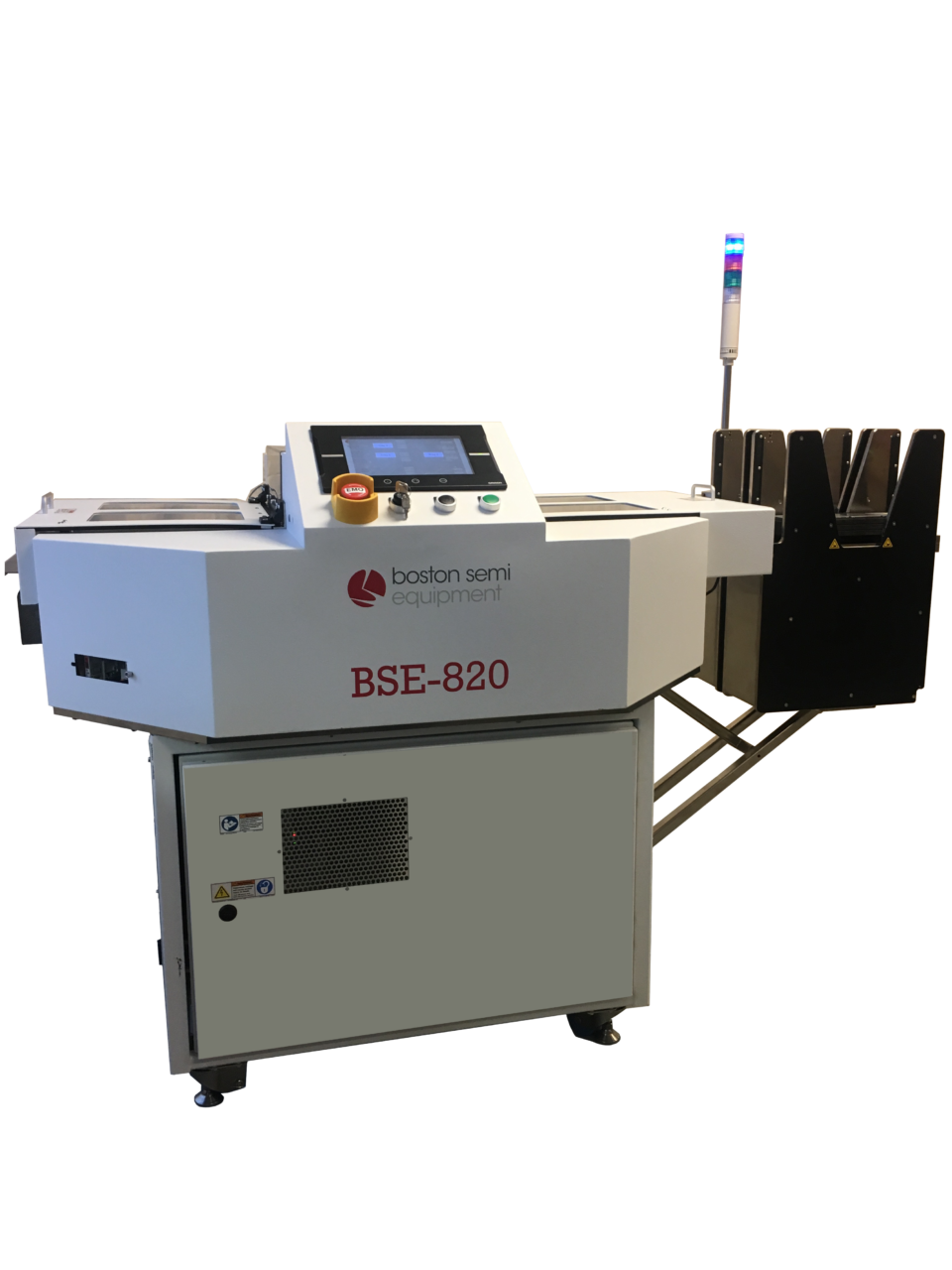

BSE-820

The compact BSE-820 series test handler is ideal for engineering and low volume production test environments. The BSE-820 uses JEDEC trays on input and output and has four manual tray positions. The BSE-820 has two (2) automated tray stacks plus two (2) manual tray positions.

The BSE-820 can convert from one package to another in thirty (30) minutes or less.

- Large IC Handler (up to 90 x 90)

- x1 to x4 Parallelism

- 2D ID For Part Traceability

- JEDEC Tray Media

- Manual Tray or Tray Automation Versions

- Four (4) Axis PnP (X, Y, Z and Rotation)

- Interface with Custom Test Setups

- Placement Accuracy of +/- 75um

- Kit Change: 30 Minutes

BSE-100

The BSE-100 is a strip load/ unload module for use in automated IC assembly lines. The automation modules handle magazines containing strips populated with semiconductor test handling devices undergoing different process steps.

The freestanding modules dock to strip-processing equipment via a SMEMA-compliant interface. Each process module communicates with the BSE-100 to control its operation. The BSE-100 can also be setup by operators using its color touch-screen monitor.

- Strip Load and Unload Module

- SMEMA-Compliant Interface

- Magazine Media

- Synchronous or Asynchronous Load/ Unload

- Touch Screen Interface